Swift Sensors

About

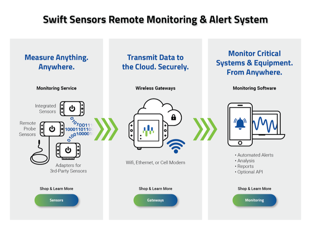

Swift Sensors is a remote monitoring and alert system enabled through low-cost, wireless sensors for food services, pharmaceuticals, facilities management, and manufacturing. Powered by sensors that measure almost anything, anywhere, Swift Sensors customers are immediately alerted of equipment failure, power outages, water events, machine vibration, unwanted activity, and more. With the data, alerts, and insights from the Swift Sensors cloud software, users can prevent catastrophic inventory loss, reduce production downtime, automate reporting tasks, and optimize processes to drive efficiency, productivity, and reliability. https://www.swiftsensors.com

Solution

- Low-cost, compact wireless sensors for measuring anything, anywhere – temperature, humidity, vibration, water events, power, activity, industrial measurements, and more.

- Advanced, secure gateways that transmit sensor data to the cloud through wifi, ethernet, or cellular modem.

- Cloud software that displays real-time and historical measurement data, generates reports for compliance inspections, and integrates with other applications through APIs.

- Monitoring and alert service that notifies users via SMS text, email, or phone call when measurements exceed warning or critical alarm levels.

Benefits

Swift Sensors remote monitoring and alert system is used in corporate, industrial, and commercial applications to deliver the following benefits:

Prevent Equipment Failure: Businesses storing perishable goods (food, raw materials, medicines, vaccines) face significant financial loss, business disruption, and erosion of customer trust and loyalty when coolers and freezers fail; resulting in potential catastrophic inventory loss and expense. Our wireless sensors monitor conditions such as temperature, humidity, power, vibration, and open doors in refrigeration systems and immediately alert managers when equipment shows signs of trouble, enabling them to act quickly and avoid losses.

Minimize Downtime Through Predictive Maintenance: Production lines and large facilities are dependent on machines to stay up and running – pumps, motors, compressors, printing and packaging, CNC, HVAC, and power. Users can monitor machines and schedule maintenance only when conditions start to degrade. Predictive maintenance has been proven to be more efficient, lower cost, and less resource intensive than scheduled or break-fix maintenance approaches.

Optimize production processes for efficiency and productivity: Using wireless sensors, users can measure production output across equipment lines, shifts, or facilities and analyze volume and efficiency to find areas for improvement and optimization.

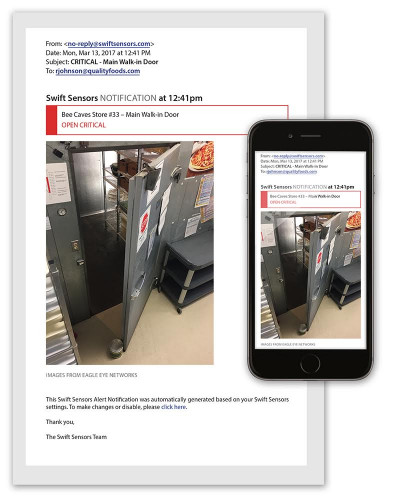

Combining Swift Sensors measurement capabilities with Eagle Eye Networks extends and enhances security monitoring capabilities, adding important context and feedback. Customers can embed a video feed from the Eagle Eye Networks VMS on a Swift Sensors dashboard with sensor measurements overlaid – so you can see the temperature, humidity, or other measurements for the area covered by the camera. In addition, Swift Sensors email notifications can include a real-time snapshot from a video camera, allowing users to view synchronized real-time video and sensor data to identify issues and quickly solve the root cause.

Demonstration

Partner Requirements

- A minimum of one sensor

- Gateway

- Annual monitoring service contract

** EEN VMS integration is included as a standard feature in the Swift Sensors Console software.

Eagle Eye Requirements

- Cameras; check EEN compatibility list

- Eagle Eye Networks bridge or camera managed video recorder (CMVR)

- Eagle Eye Networks camera subscription

Diagram

Best Practices

Communication range between the sensors and gateways can be impacted by obstacles, equipment, walls, etc. If possible, install within line of sight for best results. For harsh environments or walk-in freezers/coolers, mount the sensor on the outside and run the lead through a port, hole, or door jamb to maintain signal connectivity.